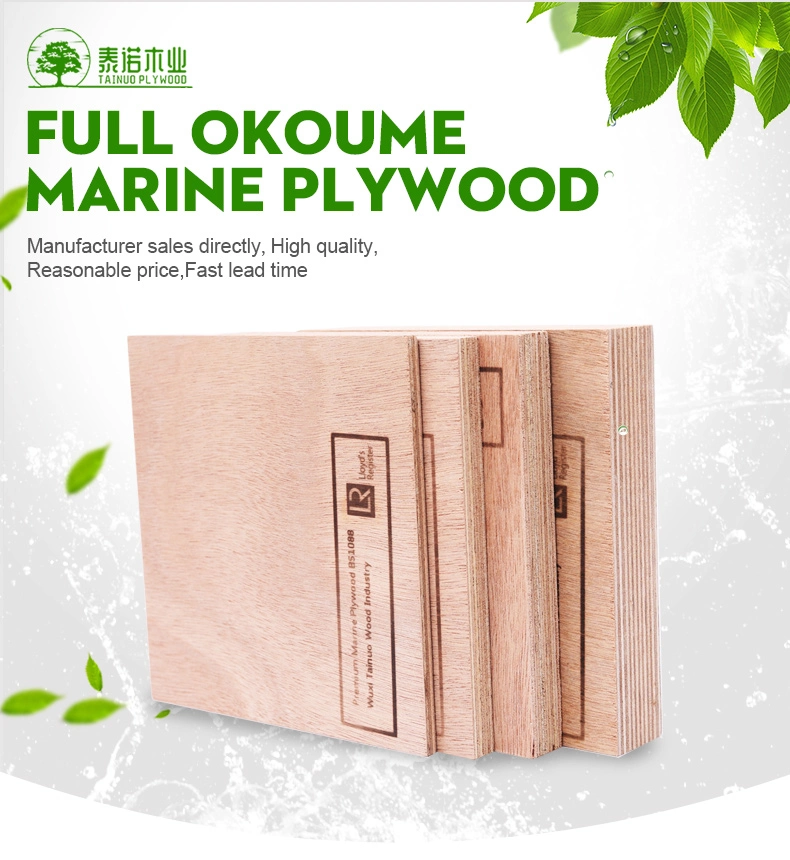

Lloyds Approved 3/4/6/9/12/15/18/25mm Okoume Marine Plywood

Basic Info.

| Model NO. | BS1088 |

| Place of Origins | China |

| Grade | Excellent Grade |

| Usage | Indoor, Outdoor |

| Delivery Time | Normally Within 10 Days |

| Price | Reasonable |

| Workers Number | About 70 |

| Productivity | 300, 000PCS/Month |

| Moisture Content | 6-14% |

| Factory | Yes |

| Payment | T/T or Others |

| Samples | Yes |

| Faced | Can Be Brown |

| Glue | WBP |

| Factory Area | 15000 Square Meters |

| Experiece | 25 Years |

| Certificate | BS 1088 |

| Thickness | 1.5/3/4/5//6mm as You Want |

| Product Name | Marine Plywood, Film Faced Plywood, etc. |

| Transport Package | Stand Wood Export Crates |

| Specification | Export Standard |

| Trademark | Tainuo |

| Origin | China |

| HS Code | 4412390090 |

| Production Capacity | 2000M3/Month |

Product Description

| Product Name: | Marine plywood |

| F&B Film: | veneer plywood (okoume) |

| Grade: | A./B |

| Core: | Okoume,birch, ,combi, hardwood,etc. |

| Glue: | WBP |

| Thickness: | 2mm-50mm |

| Specifications: | Normal size: 1220mmx2440mm,1250mmx2500mm,1530x3150 |

| Package: | Standard Seaworthy packing |

| Inner Packing: Pallet is wrapped with a 0.20mm plastic paperOuter Packing: Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |

| Loading: | 20'GP: 8pallets/22.5cbm40'GP: 16pallets/42cbm40'HQ: 18pallets/53cbm |

| Certificates: | LR, ISO9001, ISO14001 |

| MOQ: | 1 X20HC |

| Price terms: | FOB, CNF, CIF |

| Payment: | T/T, 100% irrevocable L/C at sight |

| Delivery time: | Within 20 days after receipt of the original L/C or the 30% advanced payment |

| Supply capacity: | 3000CBM/month |

| Usages: | Marine Industry such as boat building |

| More Details: | Density: 400-680kgs/m3Moisture Content: below 14%Thickness Tolearance: +/-0.3mm to +/-0.5mmModulus of Elasticity: >=5000MpaStatic Bending Strength: >=30MpaSurface Bonding Strength: >=1.60MpaInternal Bonding Strength: >=0.90MpaScrew Holding Ability: Face >=1900N ; Edge>=1200N |

FAQ: Q: Do you have BS 1088 certification papers? What about Lloyd's approval, do you have this also? A:Yes, we have the Lloyds certificate for our marine plywood Q:Are panels 100% okoume throughout? A:Yes Q:Are face/back one piece only? A:Yes Q:What is face/back veneer thickness before/after sanding? A:1.1mm before sanding and 1mm after sanding Q: Do you use WBP waterproof glue that will pass the 72 hrs boil test? For face/back, mills often use waterproof melamine glue in order to avoid glue bleed problems. A:Yes, we use 100% Dynea WBP glue for our marine plywood. Q:What is the moisture content of the panels? A:10~12% Q: Are all veneers machine dried by proper steam dryers and not just using hot press to dry? A:Yes,all veneers is dried by proper steam dryers Q:What are the thicknesses you can produce and what is the number of plies for each thickness? A:We can produce from 2mm~40mm 4mm 3plys 6mm 5plys 9mm 7plys 12mm 9plys 15mm 11plys 18mm 13plys Q:What is the final sanding grit for face/back? A:400 sanding grit for face/back Why choose us? 1, More than 20 years of professional experience, 70 skilled workers can, the capacity 60HQ every month. 2, We are not a large factory, but we will keep every promise firmly. 3, Superior quality wins us the trust from clients, quality first is always our tenet. We refine every details strictly. 4, Creation and innovation are critical for meeting the increasing demands of customers. 5, Good communication gurantees best understanding and lowest deviation. 6, Delivery on time will be ensured |